Doroti PACK operates a factory in Hungary, to develop and manufacture premium-quality packaging solutions for food and other type of products. We have more than 22 years of experience in manufacturing of thermoforming packaging machines. Each DorPack thermoforming machine is individually designed to suit special needs of customers’ and product parameters.

DorPack machines are usually used:

- for food products such as fresh meat and other butcher’s meat, fish, dairy products, bakery ware, confectionery, ready-cooked, etc.

- for healthcare products, medical and other technical devices, industrial components etc.

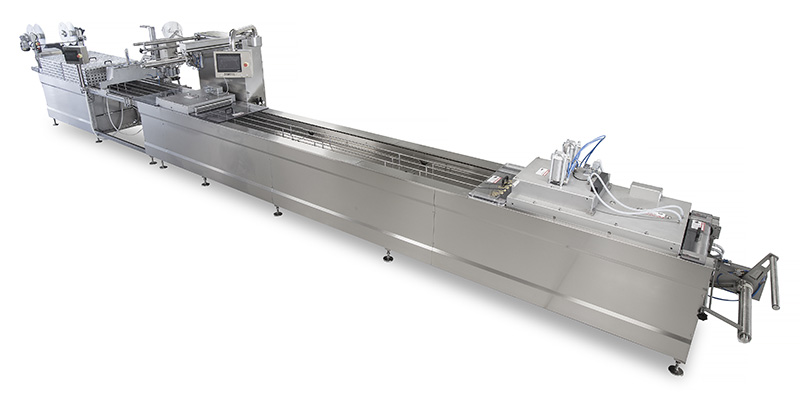

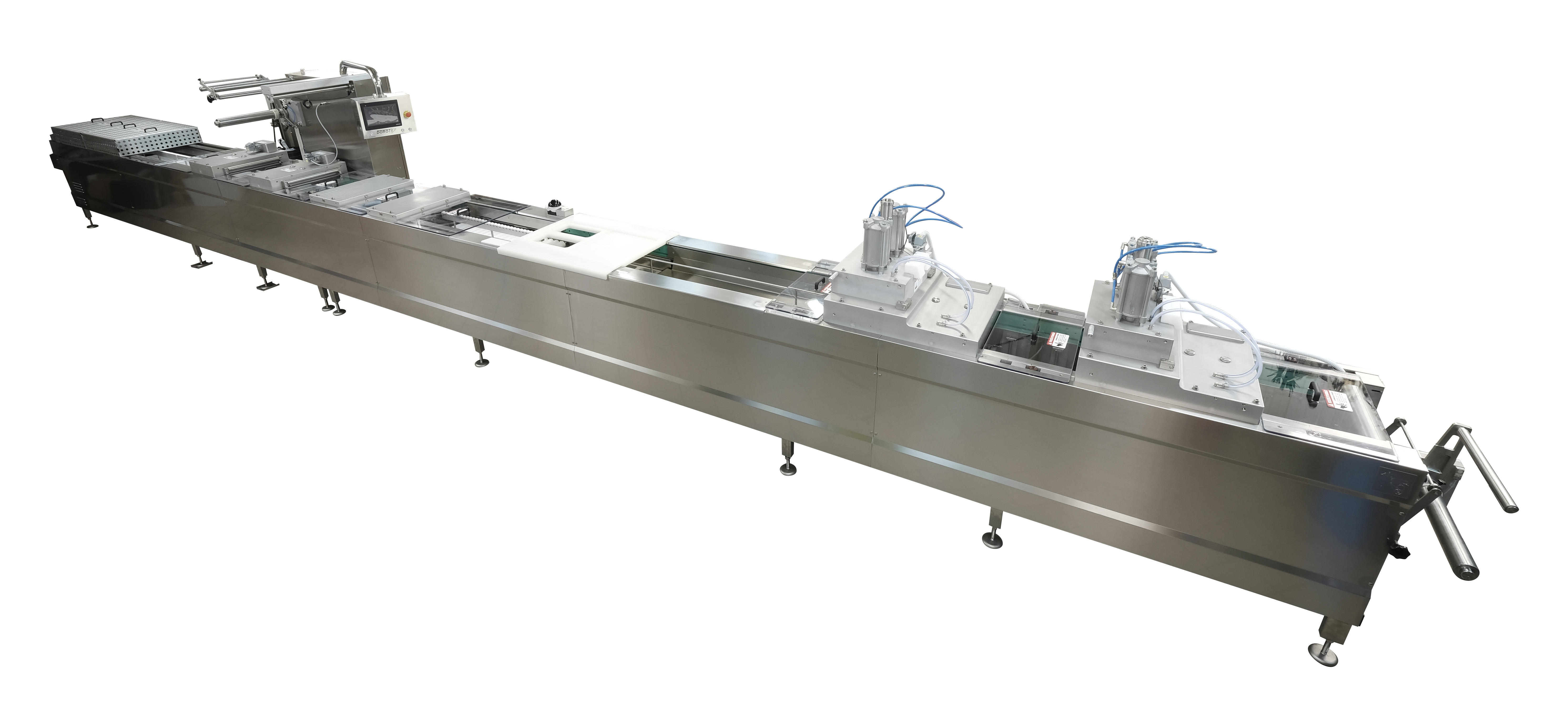

The DorPack thermoforming machines are cost-effective and good working-power saving machines. They are built with stainless steelto keep clean and hygienic operation. These machines could be used in the food-, pharmaceutical-, and in most of other industries, where the high-performance packaging is needed. High value components can be packed with atmospheric packing to protect them against mechanical and environmental influences. The machines are suitable for modified atmosphere packaging (M.A.P.). This atmosphere is usually a mix of carbon dioxide, nitrogen or oxygen. In this case M.A.P. is a natural atmosphere in the pack which is good for the product, so it keeps the storage life of the food longer. Also, packaging under vacuum extends the shelf life of the product, by removing the atmosphere, it slows down the microbial deterioration of the product. The DorPack machines are totally produced by our company and each of them fits with the customers’ need in dimensions and packing challenge. In favour of more efficient production, we manufacture the machine with double die so the replacement time of the die is being saved. Only one touch of a button and the machine makes a different format and sized package. We produce the packing die as well, so customers’ special requirements can be accepted. In many cases, there is the possibility to pack the total range of the partner’s products with one carefully designed DorPack Varia packaging die. We can help you to choose the best packaging method and with DorPack Varia format division the transformation from one to another forming depth and from one to an another package size will be very simple.

The machines also can be equipped with additional needs. Souch as labelling or printing modules and an automatic loading system. We are using components from famous European manufacturers, so the servicing goes fluently all across Europe. The machines comply with the European Union regulations and they have CE classification as well.

Packaging will help to protect your products and keep their good quality. We can develop and manufacture a DorPack thermoforming solution for your special needs. Do not hesitate to get an individual quotation from us. Fill out our quotation form which and we will get in touch with you!

| Bottom film width:420 mm |

| Top film width:420 mm |

| Diameter of the film roll:400 mm |

| Soft film prepulling:400 mm |

| Hard film prepulling:400 mm |

| Machine length:cca. 6 m – Loading and output area can be extended |

| Machine width:cca. 1 m |

| Theorical packaging capacity: 16 cycle/min |

| Bottom film width:600 mm |

| Upper film width:600 mm |

| Diameter of the film roll:400 mm |

| Soft film prepulling:800 mm |

| Hard film prepulling:400 mm |

| Machine length:cca. 8-10 m – Loading and output area can be extended |

| Machine width:cca. 1 m |

| Theorical packaging capacity: 16 cycle/min |

The packaging machine is mounted with a specific technique and in this case the thermoformer will be equipped with a double die so the time of the forming die replacement could be saved. Only one touch of a button and the machine will go with a different format and sized packages.

| Bottom film width:420 mm |

| Top film width:420 mm |

| Diameter of the film roll:400 mm |

| Soft film prepulling:400 mm |

| Hard film prepulling:400 mm |

| Machine length:cca. 8-10 m – Loading and output area can be extended |

| Machine width:cca. 1 m |

| Theorical packaging capacity:16 cycle/min |

The packaging machine is mounted with a specific technique and in this case the thermoformer will be equipped with a double die so the time of the forming die replacement could be saved. Only one touch of a button and the machine will go with a different format and sized packages.

| Bottom film width:600 mm |

| Top film width:600 mm |

| Diameter of the film roll:400 mm |

| Soft film prepulling:800 mm |

| Hard film prepulling:500 mm |

| Machine length:cca. 8-10 m – Loading and output area can be extended |

| Machine width:cca. 1 m |

| Theorical packaging capacity: 16 cycle/min |